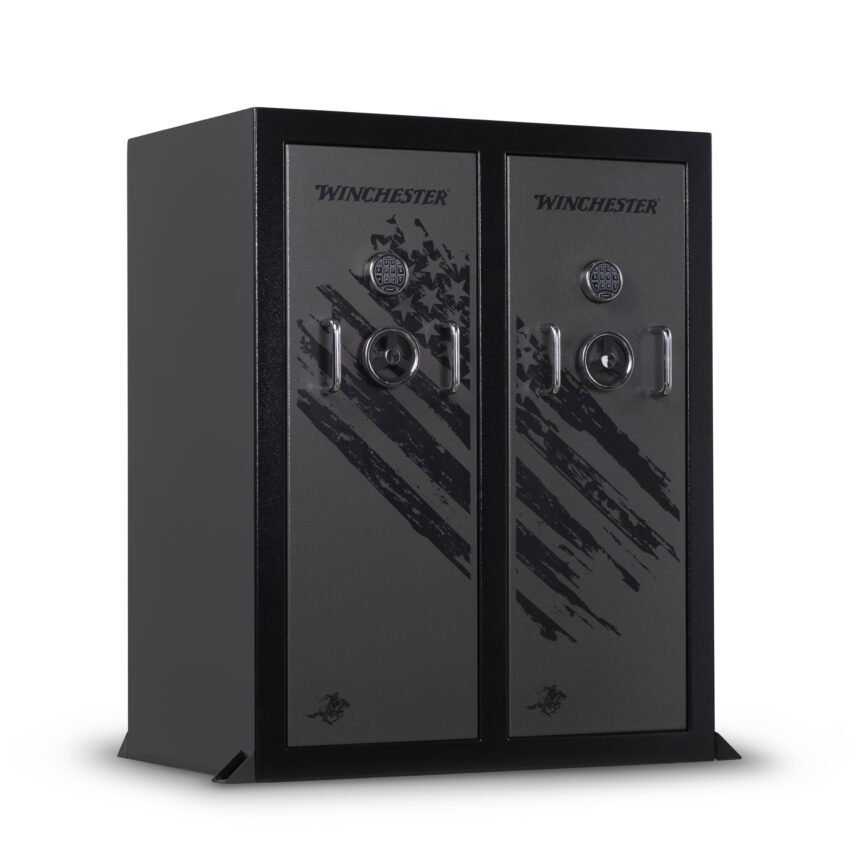

When it comes to home security, few names evoke the same level of trust and reliability as Winchester. The brand is synonymous with quality firearms, outdoor equipment, and safes. Among security-conscious consumers, Winchester safes are prized for their durability and advanced features. However, one question often arises: where are Winchester safes made? Understanding the origin of these products offers insight into their construction quality and overall reliability. This article explores the history, manufacturing process, geographical locations, and quality assurance systems that contribute to the excellence of Winchester safes.

A Brief History of Winchester Safes

The Winchester Brand Legacy

Winchester has a storied history that goes back to the 19th century. Founded in 1866, the Winchester Repeating Arms Company initially gained fame for producing rifles, with their most famous product being the Winchester Model 1873. This rifle earned the nickname “The Gun That Won the West,” establishing the Winchester brand as a household name. Over the years, it diversified its product line, introducing everything from ammunition to outdoor gear. In the latter part of the 20th century, the brand expanded into the realm of security, specifically safes. The incorporation of the Winchester brand into the safe market was a strategic move to leverage brand recognition and assure customers of high-quality security products.

Evolution of Winchester Safes

The introduction of safes under the Winchester name revolutionized the concept of home security. The first Winchester safes came to market as a response to growing consumer demand for better security solutions in homes, especially for firearms and sensitive documents. Their products combine traditional craftsmanship with modern technology. By fusing elements of aesthetics and functionality, Winchester safes quickly became popular among homeowners seeking reliable storage solutions for everything from firearms to valuables. This change reflected a broader trend as consumers began to prioritize safety and security in their households. Over time, the company refined its offerings, adapting to the evolving needs of a diverse customer base, from recreational hunters to urban dwellers.

Manufacturing Locations of Winchester Safes

U.S. Manufacturing

A significant portion of Winchester safes is manufactured in the United States. The brand prides itself on American craftsmanship, asserting that manufacturing in the U.S. guarantees a higher standard of quality and control. Key facilities in the U.S. not only handle fabrication but also play essential roles in design and innovation. By keeping manufacturing domestic, Winchester can oversee production closely, ensuring that each safe adheres to the high standards that customers expect from the Winchester name. This focus on local manufacturing not only bolsters the local economy but also provides employment opportunities, stabilizing communities where production takes place.

International Manufacturing

While a significant number of safes are made domestically, Winchester has also developed partnerships for manufacturing overseas. These international locations often specialize in specific components or features that complement the overall design of the safes. For instance, some parts may be produced in factories in China or other regions, where modern production techniques can yield high-quality components at competitive prices. Leveraging global manufacturing capabilities allows Winchester to optimize its production processes and pass savings on to consumers. By combining domestic manufacturing expertise with international production capabilities, Winchester ensures a diverse and efficient supply chain that maintains the quality and security that its customers rely upon.

The Production Process of Winchester Safes

Design and Engineering

The production of Winchester safes begins with an intensive design and engineering process. Skilled engineers collaborate to develop cutting-edge designs that prioritize user needs, safety, and aesthetics. Feedback from customers often informs the design process, ensuring that new models meet the demands of modern consumers. Each safe goes through a series of conceptual phases before reaching the production stage. Computer-aided design (CAD) software plays a vital role in this process, allowing for precise measurements and intricate designs catering to varying user preferences. This rigorous design phase is crucial for creating safes that not only secure valuables but also fit seamlessly into diverse home aesthetics.

Material Selection and Sourcing

Once the design is finalized, the next step involves choosing the right materials. Winchester takes pride in selecting high-quality steel, advanced locking mechanisms, and durable finishes for their safes. The company ensures that materials can withstand impacts, resist unauthorized access, and provide optimal fire protection. Winchester sources materials from trusted suppliers, often conducting tests to ensure they meet the stringent quality criteria established by the company. This level of diligence in material selection reflects Winchester’s commitment to quality and security, giving consumers confidence in their products. Additionally, the emphasis on premium materials often results in a longer lifespan for the safes, providing real value over the years.

Fabrication and Assembly

The actual manufacturing process begins when the raw materials arrive at the factory. Skilled workers employ advanced machinery to fabricate each component of the safe, including the body, door, and internal shelving. These components are crafted with precision, as even the smallest errors can lead to significant vulnerabilities in functionality. Once all components are prepared, assembly begins. During this stage, workers meticulously piece together the individual parts, ensuring that each safe meets Winchester’s strict quality control standards. The assembly process is a collaborative effort that involves attention to detail at every step, with experienced technicians continuously checking for accuracy and quality.

Quality Control Measures in Manufacturing

Rigorous Testing Protocols

Quality assurance plays a crucial role in ensuring the reliability of Winchester safes. The company employs rigorous testing protocols throughout the manufacturing process. Each safe is subjected to various tests, including drop tests, fire resistance evaluations, and lock functionality assessments. Engineers simulate real-world conditions, identifying any potential weaknesses before the products reach the market. This extensive testing helps ensure that each safe can withstand various challenges it may encounter in everyday use. By prioritizing quality control, Winchester builds products that inspire trust and confidence among consumers.

Certification and Compliance

Winchester ensures that all safes comply with industry standards and regulations. This certification guarantees that their products are not just secure but also adhere to safety guidelines beneficial to consumers. The brand works closely with independent testing organizations to validate claims regarding fire resistance, security, and build quality. These certifications add an extra layer of credibility to the brand and provide peace of mind for customers making a purchase. Winchester also remains proactive in adapting its products to comply with changing regulations and industry standards, ensuring that customers receive safe and effective storage solutions.

Features of Winchester Safes

Advanced Security Features

Winchester safes offer numerous advanced security features designed to protect your valuables effectively. Many models incorporate such features as electronic locks, biometric fingerprint scanners, and dual-lock mechanisms. These options provide users with flexibility and enhanced security, allowing individuals to choose according to their personal preferences. Enhanced security ensures that only authorized individuals can access the contents, providing invaluable peace of mind for homeowners. Additionally, the integration of smart technology allows some models to connect to mobile apps for monitoring and management, pushing the boundaries of traditional safe functionality.

Fire and Water Resistance

In addition to theft protection, Winchester safes are designed to withstand extreme conditions, including fire and water damage. Many safes come equipped with fire-resistant materials that can protect contents for several hours at elevated temperatures. This feature is especially critical for valuables like important documents and firearms. Additionally, models designed for flood-prone areas feature watertight seals to safeguard valuables in case of water intrusion. This focus on safety against environmental threats makes Winchester safes a smart choice for safeguarding critical items. Customers can rest assured that their possessions are protected not only from theft but also from the unpredictability of natural disasters.

Customer Support and Warranty

Comprehensive Customer Service

Winchester takes customer satisfaction seriously. Their support team is readily available to assist with questions or concerns about products, installation, or usage. They offer live chat, phone assistance, and email support, ensuring that customers receive timely help when needed. The company also provides extensive resources online, including manuals, FAQs, and installation guides, empowering customers to maximize the efficiency and functionality of their safes. This dedication to customer service builds loyalty and trust, providing a safety net for users who may have pressing concerns or technical queries.

Warranty Options

A strong warranty policy reflects a company’s confidence in its products. Winchester safes come with a limited lifetime warranty that covers defects in materials and workmanship. This warranty provides peace of mind for consumers, reassuring them that they are making a smart investment. Should issues arise, customers can feel secure knowing they have options to address any problems that may develop down the line. Such warranty options enhance the purchasing experience and reinforce trust in the brand, as consumers know they are protected even after the initial sale.

The Legacy of Winchester Safes

In summary, Winchester safes are synonymous with quality and security, backed by a long-standing legacy of excellence in manufacturing. Understanding where Winchester safes are made, their production process, and the features they offer helps consumers make informed choices. From their rigorous quality control measures to advanced features that prioritize security, Winchester delivers products designed to meet the needs of every customer.

Consumers should feel confident about choosing a Winchester safe, knowing that they are investing not only in a product but in decades of craftsmanship and expertise. Whether you’re safeguarding firearms, important documents, or cherished keepsakes, a Winchester safe represents a reliable investment in home security. There’s more to a safe than just how it looks; it’s about how well it performs and how effectively it protects what matters most. So explore the various offerings from Winchester, and join countless customers who trust this iconic brand for their storage needs. The peace of mind that comes with a Winchester safe is not just a feature; it is an essential part of their trusted legacy in security solutions.