Introduction to Hard Hat Expiration Dates

Hard hats play a crucial role in ensuring the safety of workers in various industries, particularly on construction sites. They protect against head injuries resulting from falling objects, bumps, and other hazards. However, a hard hat is not a permanent solution. Like all safety equipment, hard hats have a limited lifespan and an expiration date, which is critical to understand. Knowing how to read hard hat expiration date is essential for maintaining safety and compliance on the job. This article will delve into the importance of expiration dates, how to identify them, and best practices for hard hat care and maintenance.

Importance of Knowing Hard Hat Expiration Dates

Understanding expiration dates is vital for anyone who uses hard hats regularly. Over time, hard hats can degrade due to exposure to ultraviolet (UV) light, extreme temperatures, and physical wear and tear. As they age, their protective qualities diminish, placing workers at risk of injury. Most manufacturers design their hard hats to provide maximum protection for a certain period, often up to five or seven years, depending on the material and conditions of use.

The significance of knowing how to read hard hat expiration date cannot be overstated. Regularly checking expiration dates can help prevent accidents and ensure that protective gear is always reliable. Moreover, many regulatory agencies impose safety standards which mandate that safety equipment, including hard hats, are inspected periodically. Ignoring these guidelines can lead to serious injuries and heighten the risk for workers on-site.

Understanding How to Read Hard Hat Expiration Dates

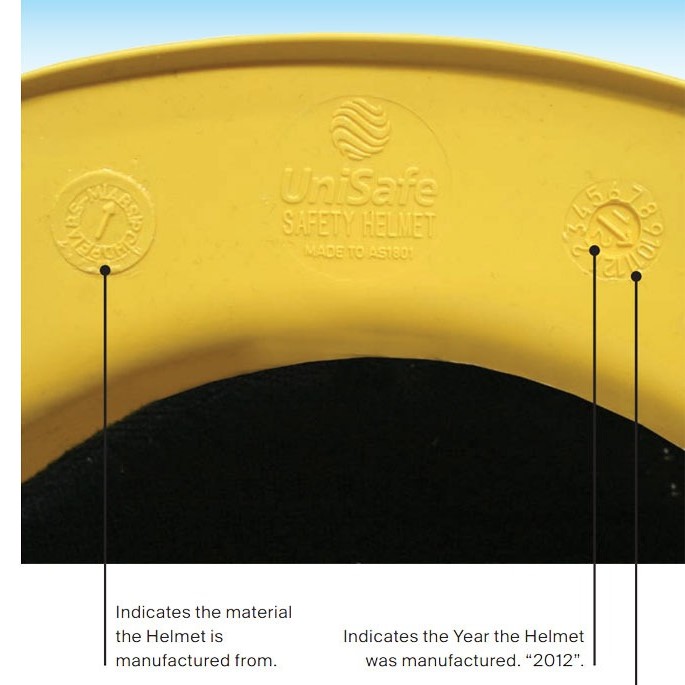

Typically, the expiration date or the date of manufacturing is printed on a label located on the inside of the hard hat’s shell. Manufacturers may use different formats, but most common are variations of numerical and alphabetic representations indicating the month and the year of manufacture.

Key Elements to Look For:

Manufacture Date

- Definition: The manufacture date refers to the date when the hard hat was produced and can be found on the internal label of the helmet.

- Format: This date is typically displayed as a numerical code, which indicates both the month and the year of manufacture. Common formats are “MM/YYYY” and “MM/YY.”

- Importance: Knowing the manufacture date is crucial, as it serves as the starting point for determining the hard hat’s usable life and expiration date.

- Example: If a hard hat has a manufacture date of “03/2022,” this means it was made in March 2022. Thus, any lifespan calculations should begin from this date.

Lifespan Information

- Expected Lifespan: Most manufacturers provide clear information regarding the expected lifespan of their hard hats, generally establishing it at five years from the manufacture date.

- Conditions Affecting Lifespan: Under optimal conditions—such as proper storage, minimal exposure to harmful environments, and appropriate levels of usage—some hard hats may maintain their integrity for up to seven years.

- Manufacturer Variability: It’s essential to consult the specific manufacturer’s guidelines, as different brands or models may have varying lifespans based on their design and materials.

- User Responsibility: Workers should track the time since the manufacture date and ensure that they replace their hard hat once it nears the end of its designated lifespan, regardless of its physical appearance.

Warnings and Guidelines

- Reading Warnings: Carefully review any specific warnings and guidelines provided with the hard hat. These may address the helmet’s maintenance, usage, or conditions under which its integrity could be compromised.

- Impact of Chemicals: Certain chemicals can negatively affect the materials used in hard hats, leading to premature degradation.

- Heat Exposure: Extreme heat can also accelerate the deterioration of hard hats. Guidelines often recommend avoiding leaving hard hats in direct sunlight or inside hot vehicles, as prolonged exposure can compromise their protective capabilities.

- Importance of Compliance: Following these warnings and guidelines helps ensure the continued effectiveness of the hard hat, thus enhancing safety in hazardous work environments. Disregarding them could result in using a compromised safety device, increasing the risk of workplace injuries.

By being vigilant about these details, workers can effectively manage the lifespan of their hard hats and mitigate safety risks.

FAQs Regarding Hard Hat Expiration Dates

To further enhance understanding, let’s explore some frequently asked questions about hard hat expiration dates.

Does a Hard Hat Have an Expiry Date?

Yes, hard hats indeed have an expiration date. The date at which a hard hat is deemed no longer effective is usually indicated on its internal label. Recognizing this date is essential for maintaining workplace safety.

How to Check if a Hard Hat is Out of Date?

To determine whether a hard hat is out of date, locate the manufacture date and the recommended lifespan. If the current date surpasses the lifespan indicated by the manufacturer, the hard hat must replace. Additionally, inspect it for any signs of wear or damage, as these factors can compromise its effectiveness, regardless of its age.

How Do You Read the Expiration Date Format?

Expiration dates may be presented differently based on the manufacturer. The two common formats are “MM/YYYY” or “MM/YY.” Make sure to refer to the manufacturer’s guidelines to understand the expected lifespan for that specific model.

How to Tell if a Helmet is Expired?

In addition to checking the expiration date, physical condition plays a significant role in assessing whether a hard hat has expired. Look for visible signs of wear, such as cracks, dents, or discoloration due to UV exposure. If any of these are present or if the expiration date has passed, it’s time to replace the helmet.

Best Practices for Hard Hat Maintenance

To ensure the longevity and effectiveness of hard hats, implementing best practices for maintenance is crucial.

Regular Inspections

Conduct regular inspections of your hard hat. Look for any cracks, scratches, or signs of wear. A quick visual check can often reveal much about your hard hat’s condition.

Proper Storage

Store hard hats in a cool, dry place away from direct sunlight and extreme temperatures. Avoid leaving them in vehicles or areas that may not provide appropriate conditions, as excessive heat can accelerate deterioration.

Cleaning and Care

Cleaning Method:

-

- Mild Soap: Use a mild soap to clean your hard hat. Avoid anything abrasive that could scratch or damage the surface.

- Warm Water: Mix the soap with warm water, as this combination is effective in removing dirt, grease, and grime without causing harm to the helmet’s material.

- Wiping Down: Regularly wipe down the helmet using a soft cloth or sponge. This preventative measure ensures that contaminants do not accumulate over time.

Avoiding Harmful Substances:

-

- Harsh Chemicals: Refrain from using any harsh chemicals or solvents when cleaning your hard hat. Substances such as bleach, acetone, or paint thinners can degrade the plastic and other materials, compromising the helmet’s protective features.

- Chemical Exposure Awareness: Be aware of the specific manufacturing materials and any accompanying recommendations regarding cleaning, as different hard hats may have unique care instructions.

Care for Removable Components:

-

- Straps and Liners: Many hard hats come with removable straps and liners that can be cleaned separately.

- Manufacturer’s Instructions: Always follow the manufacturer’s instructions for washing these components. Some may be machine washable, while others could require hand washing with mild soap.

Drying Process:

-

- After cleaning, ensure that you allow the hard hat and any removable components to dry completely before reusing them. Avoid using heat sources, such as hair dryers or direct sunlight, as these can warp or damage the materials.

- Routine Maintenance: Incorporate cleaning and care routines into your regular maintenance schedule. Routine checks and cleaning sessions not only prolong the life of your hard hat but also enhance comfort and safety while wearing it.

- Inspection After Cleaning: After cleaning your hard hat, take the opportunity to inspect it for any signs of wear or damage. Look for cracks, dents, or other impairments that could affect its protective capabilities, and replace it if necessary.

Replacement of Accessories

If your hard hat has additional components, such as a chin strap, sweat band, or visor, ensure that these parts are also in good condition.

Educating Workers for Enhanced Safety

In addition to following these guidelines, education and awareness are crucial. Conduct training sessions that emphasize the importance of understanding hard hat expiration dates. Sharing knowledge about potential hazards linked to outdated safety gear can encourage workers to take responsibility for their safety.

Consider creating easy-reference guides that outline how to read expiration dates and inspect hard hats. Providing accessible information can empower workers to make informed decisions regarding their protective gear.

The Role of Employers in Safety Compliance

Employers have a vital role in ensuring the safety of their workforce. This includes providing appropriate training and ensuring that everyone understands how to read hard hat expiration dates. Regular safety audits should conduct to ensure compliance with safety standards related to hard hats.

Employers should also foster an environment where workers feel comfortable reporting concerns about outdated or damaged safety equipment. Creating a culture of safety encourages everyone to contribute to a safer workplace.

Conclusion

In conclusion, knowing how to read hard hat expiration date is vital for maintaining safety on construction sites and other environments where hard hats are necessary. Regularly check the expiration date to ensure compliance with safety regulations, and always inspect your hard hat for signs of damage. Proper maintenance and education can significantly mitigate risks, ensuring a safer workplace for everyone involved.

By prioritizing the understanding of hard hat expiration dates and adhering to maintenance best practices, employers and workers alike can protect themselves and their colleagues. Safety is not just an individual responsibility; it is a collective commitment that requires continuous awareness and action. Stay informed and make safety a priority in your work environment.