Introduction: The Importance of Hard Hat Expiration Dates

In today’s workplace, especially in construction and industrial settings, personal protective equipment (PPE) is crucial to ensuring the safety and well-being of workers. Among the most important pieces of safety gear are hard hats. Understanding how to read hard hat expiration dates is critical for maintaining safety standards on the job. Each hard hat comes with a specified lifespan, and using an expired hard hat may jeopardize your safety and lead to severe injuries.

Hard hat expiration dates are often overlooked by workers who assume these helmets don’t have a lifespan. However, hard hats can degrade over time due to environmental factors like sun exposure, humidity, and physical wear and tear. In this article, we will delve deep into the intricacies of hard hat expiration. We will provide essential information on how to read expiration dates, why they are important, and what steps you can take to ensure your hard hat will provide the necessary protection.

What Is a Hard Hat Expiration Date?

Definition and Importance

- What It Means: A hard hat’s expiration date signifies the period during which the helmet is expected to provide adequate protection. After this date, the integrity of the helmet may be compromised, making it less effective against impacts or penetrating objects.

- Safety Implications: Wearing an expired hard hat can result in serious injury during accidents. It is essential to adhere to these expiration guidelines to ensure your safety and that of those around you.

How to Find the Expiration Date

- Location of the Date Stamp: How to read hard hat expiration? The expiration date is typically located inside the hard hat, printed on a label or embossed into the shell. Manufacturers often place this information under the padding or at the back of the helmet.

- Identifying the Format: Manufacturers utilize different formats for expiration dates. Familiarize yourself with your hard hat’s specific way of encoding the date to avoid confusion.

Understanding Hard Hat Lifespan

Factors Affecting Lifespan

Material Composition

Common Materials Used

- High-Density Polyethylene (HDPE): One of the most common materials used in hard hat construction, HDPE is known for its durability and resistance to impact. It offers excellent protection from falling objects and can withstand various environmental conditions.

- Fiberglass: Fiberglass hard hats provide robust protection and are lightweight. They offer superior impact resistance and can molde to meet specific safety standards. However, fiberglass can be more expensive than plastic options.

Degradation Factors

- UV Ray Exposure: Hard hats are often exposed to UV rays from sunlight, which can degrade the materials over time. Prolonged exposure may cause the hard hat to become brittle and less effective at absorbing impacts.

- Chemical Exposure: In many work environments, hard hats come into contact with chemicals, including solvents, paints, and cleaning agents. These chemicals can compromise the integrity of the helmet materials, leading to reduced effectiveness.

- Extreme Temperatures: Extreme heat or cold can also impact hard hat materials. High temperatures can cause certain plastics to warp or deform, while cold temperatures may make materials more rigid and susceptible to cracking.

Nature of Use

Impact of Usage Environment

- Harsh Work Conditions: The lifespan of a hard hat can diminish rapidly when exposed to harsh environments such as construction sites, where workers are at risk of falling objects, heavy machinery operation, and other physical hazards.

- Frequency of Use: Regular use in rugged conditions leads to wear and tear, increasing the likelihood of cracks, dents, and visible damage. The more frequently a hard hat use in demanding settings, the more regularly it should inspect and potentially replace.

Importance of Inspections

- Regular Damage Checks: It’s essential to perform routine inspections of your hard hat for any signs of damage. Checking for cracks, scratches, or fading can help determine whether the helmet still provides adequate protection.

- Replacing Damaged Hats: If any damage is identified, the hard hat should replace immediately. Wearing compromised equipment can lead to severe injuries, particularly in hazardous work environments.

Manufacturer Specifications

Varying Lifespan Guidelines

- Manufacturer Influence: Different manufacturers establish varied lifespans for their hard hats based on materials, testing, and safety standards. The lifespan can affect by the specific use case and environmental conditions.

- General Recommendations: Some manufacturers may recommend that hard hats should replace every two to five years, depending on factors like wear, material fatigue, and exposure to damaging elements.

Understanding Product Information

- User Manuals and Labels: It’s crucial to always review the user manual or instructions provided with your hard hat, as they contain important information about the recommended replacement schedule and care instructions.

- Compliance with Regulations: Always ensure that hard hats comply with local safety regulations and ANSI standards. Organizations often specify deadlines for replacing safety equipment based on the manufacturer’s guidelines, which can vary widely within the industry.

The Role of Standards

- Compliance with Regulations: The American National Standards Institute (ANSI) and other organizations establish guidelines for hard hat lifespan and performance. Familiarizing yourself with these can help you understand acceptable safety standards.

- Maintenance and Care: Proper care and maintenance can significantly extend the life of a hard hat. Avoiding exposure to extreme temperatures and cleaning the helmet regularly can help maintain its integrity.

How to Read Hard Hat Expiration Dates

Step-by-Step Guide

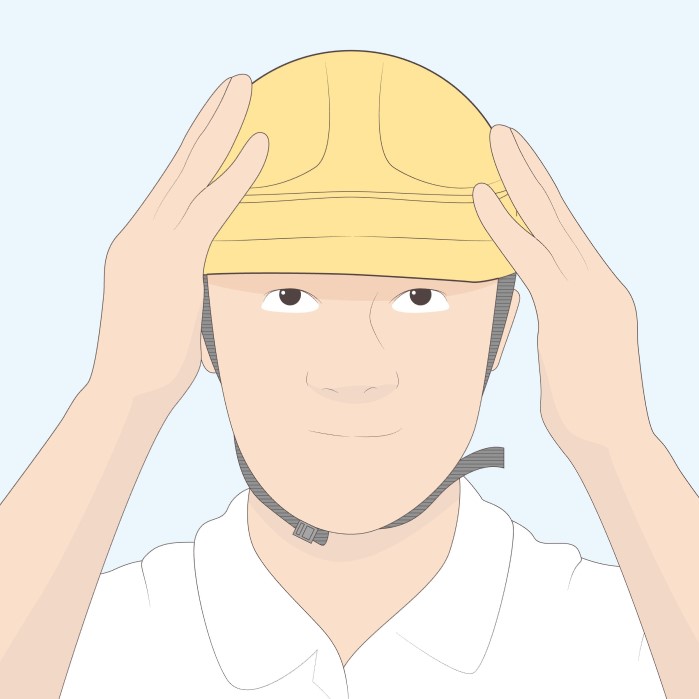

- Locate the Label: How to read hard hat expiration? First, remove the hard hat and inspect its interior. Identify the spot where the labeling or date stamp is located.

- Decipher the Code: Depending on the manufacturer, the expiration date might encode. Some manufacturers opt for a numerical code that entails the month and year of manufacture. For example, if you see “12/25”, this indicates the hard hat should replace by December 2025.

- Understand Lifespan Guidelines: Each manufacturer provides a guideline regarding the appropriate lifespan of their products. If your hard hat is within the specified time frame, it is likely safe to use. If it is nearing expiration, you should consider replacing it.

- Check for Additional Markings: In addition to expiration dates, some hard hats may contain markings about maintenance or inspection schedules. Keep an eye out for these invaluable details.

Best Practices for Hard Hat Safety

Regular Inspections

- Visual Checks: Conduct regular inspections of your hard hat for any signs of damage or wear. Look for cracks, dents, or any fading that might compromise its structural integrity.

- Functional Testing: Test the fit and adjustment of your hard hat regularly. Make sure the headband and suspension system are intact and functional.

Establishing a Maintenance Routine

- Create a Schedule: Establish a maintenance schedule that includes routine inspections and cleaning. Depending on your work conditions, this might be monthly or quarterly.

- Documentation: Keep records of inspections and replacements. Documenting these can also help managers in monitoring the safety compliance of all workers.

Frequently Asked Questions (FAQ)

How to read a coded expiration date?

To read a coded expiration date, locate the date stamp or label on the inside of the hard hat. The code will usually include a mixture of numbers indicating the month and year of manufacture. Example: “0419” represents April 2019.

What is the expiry of a hard hat?

The typical expiry of a hard hat ranges from 2 to 5 years, based on materials and manufacturer guidelines. It is crucial to check the specific expiration guidelines for your hard hat.

How to tell if a helmet is expired?

To tell if a helmet is expired, look for the date stamp or label. If the marked expiry date has passed, it’s time to replace the hard hat for safety reasons.

What does the date stamp on a hard hat mean?

The date stamp on a hard hat indicates when the helmet was manufactured and, by convention, outlines the product’s lifespan. It’s essential for assessing whether the helmet is still effective for protection against head injuries.

Conclusion: Promoting Workplace Safety Through Awareness

In conclusion, knowing how to read hard hat expiration dates is crucial for maintaining a safe working environment. Regularly inspecting hard hats, understanding expiration dates, and adhering to manufacturer guidelines can save lives.

As we’ve discussed, hard hats do have a finite lifespan, and using one beyond its expiration date can compromise your safety drastically. By actively monitoring the condition of your hard hat, you are taking essential steps toward ensuring your safety on the job.

Remember, safety is a collective responsibility, and every worker should prioritize keeping their protective gear up to date. Stay informed, keep your equipment maintained, and ensure that you—and your colleagues—are always protected. Embrace the safety culture in your workplace, and commit to ongoing education about safety equipment like hard hats to mitigate risks effectively.